Awarded supply ( lng regulator pressure, valves, valves and etc) installation of LNG line with chimney and platform

Read moreAbout Us

AL OTAIBI.Est is a leading provider of construction, metal fabrication, equipment installation, and industrial maintenance services, catering to the diverse needs of industrial and process clients across the Middle East. Committed to excellence, we deliver high-quality engineering solutions that adhere to international industry standards and consistently exceed client expectations. As a trusted partner in the Middle East, AL OTAIBI specializes in delivering advanced industrial solutions for process industries, including oil & gas, petrochemical, and manufacturing sectors — addressing unique technical challenges with precision, reliability, and expertise.

Contact UsAbout Al-Otaibi Contracting Company

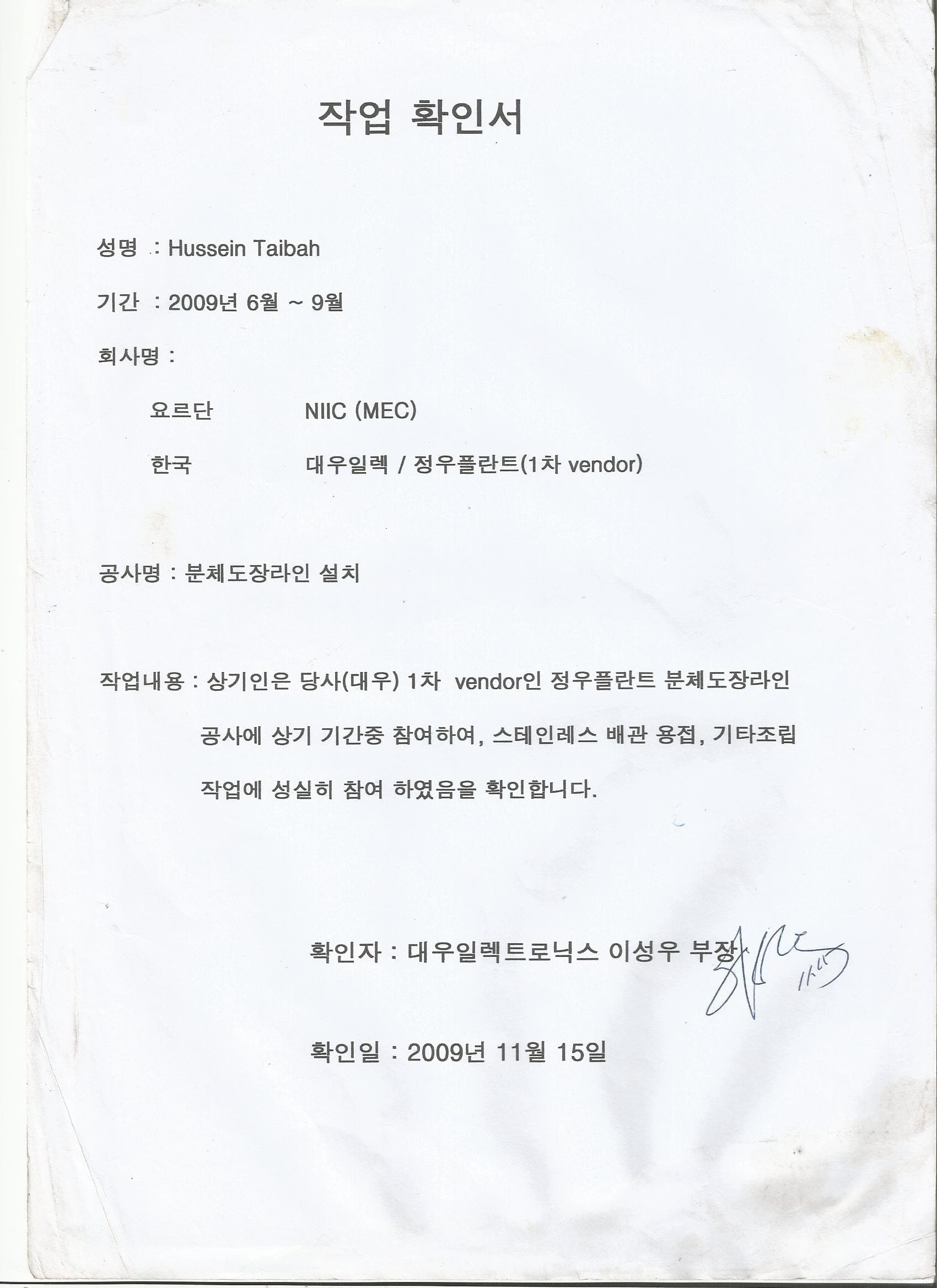

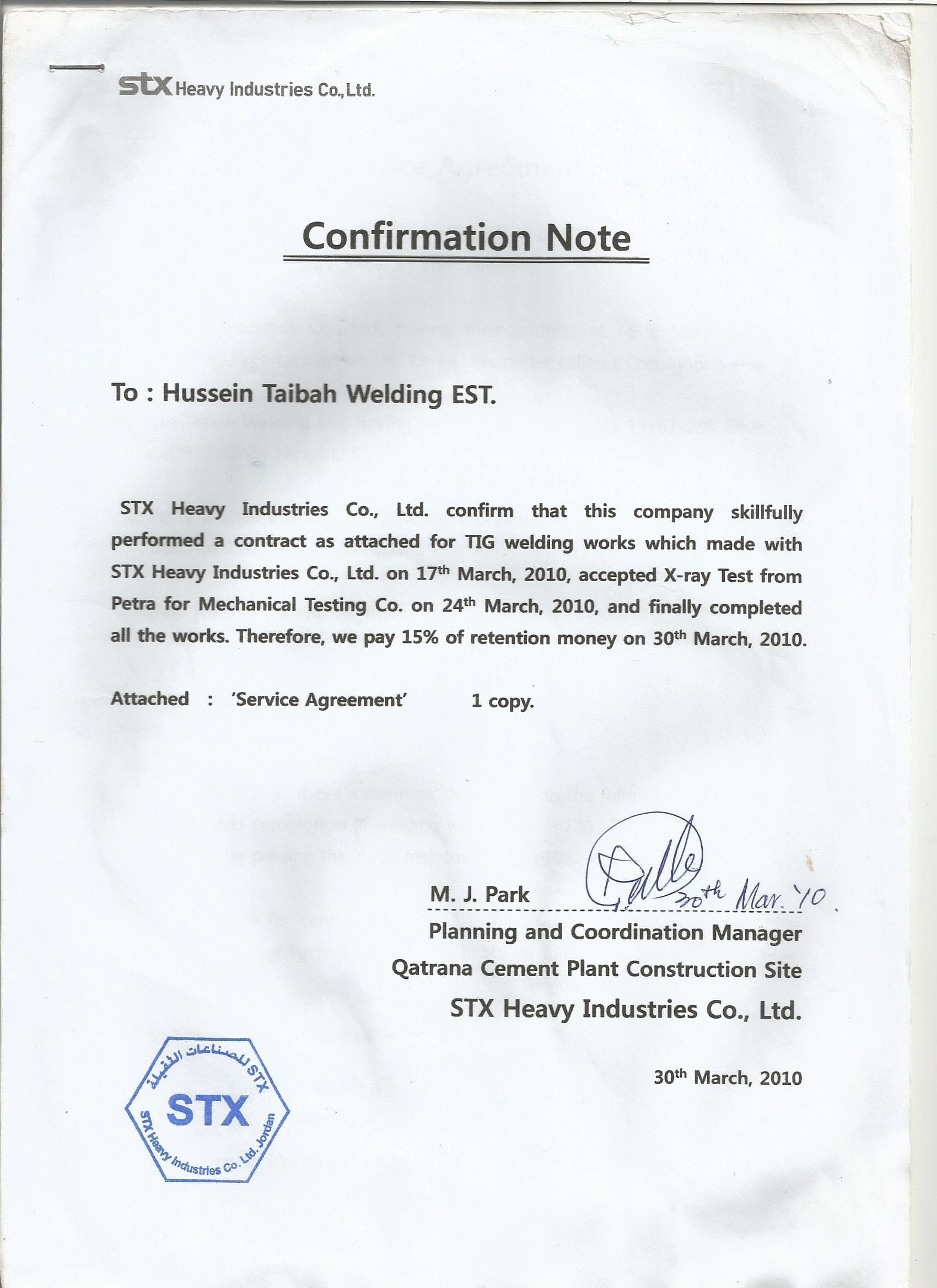

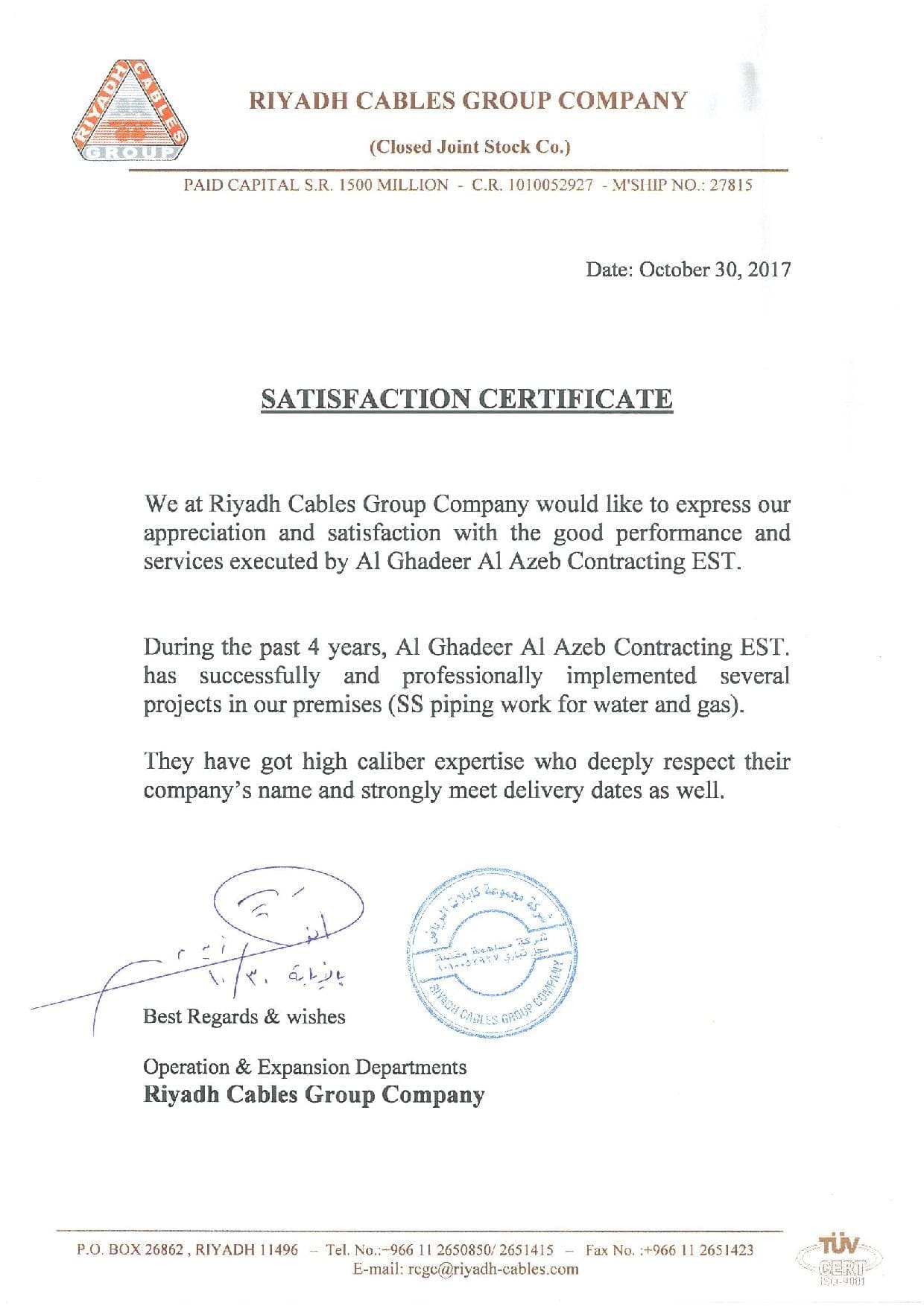

Al-Otaibi Contracting was established in 2008 as a local enterprise specializing in industrial services and metal fabrication. From the very beginning, the company focused on delivering high-quality solutions for sectors such as oil & gas, energy, and manufacturing. Driven by a commitment to precision, safety, and engineering excellence, Al-Otaibi has steadily grown into a trusted name in the fabrication of pressure vessels, skid-mounted systems, and heavy industrial components. Our journey reflects a strong dedication to long-term sustainability, advanced technology, and compliance with international standards.

Company Achievements

Categories

Newsletter Subscription

Subscribe to our newsletter to receive updates on our company’s products, news, and special offers.

Our Services

Cooling & Heating Systems

AL OTAIBI Company specializes in manufacturing and installing water cooling towers, industrial chillers, and water heating boilers for swimming pools, hospitals, and hotels. We also produce steam boilers and provide comprehensive hot and cold process heating and cooling solutions, strictly adhering to ASME, API, and ASTM standards. Our expertise ensures high-quality, reliable, and energy-efficient industrial HVAC and process equipment solutions.

Structural Steel Fabrication & Installation

AL OTAIBI Company specializes in precision fabrication and professional installation of structural steel for industrial and commercial projects. Our off-site steel fabrication process reduces on-site adjustments, accelerates project timelines, and ensures superior quality and durability. We emphasize sustainable construction by utilizing steel containing up to 88% recycled materials, with fully recyclable structural components at the end of their lifecycle. Our use of advanced fabrication technology enhances dimensional accuracy, improves worker safety, and lowers overall project costs. Structural steel offers long-lasting strength, cost efficiency, and design flexibility, enabling faster project delivery, reduced maintenance, and visually appealing, adaptable frameworks.

Tanks

AL OTAIBI Company specializes in fabricating high-quality steel tanks and pressure vessels, including ASME Section VIII, Division 1 certified vessels, lube oil tanks, oil-water separators, fire-rated tanks, ventilation overcasts, and underground mine support arches. Our ASME pressure vessels are constructed using certified welding procedures, inspected by Level III technicians and AWS-certified inspectors, and supported by extensive welder training to ensure maximum safety and reliability.

General Piping Works

AL OTAIBI Company provides a full spectrum of industrial piping services, including hot tapping, coded welding (P1, P2 & P9), mechanical maintenance, labor hire, design & build projects, consultancy, and CDM registration support. We specialize in non-destructive testing (NDT), welding inspection, surface preparation with shot blasting, industrial painting, and protective coating. Our certified engineers ensure strict compliance with international standards, while our skilled pipe welding team delivers precise, efficient, and durable piping solutions customized to client requirements.

Our Production

We manufacture and supply a comprehensive range of high-quality industrial equipment parts, essential engineering components, and vital resources for manufacturing, construction, and diverse industrial sectors. Our products adhere to strict industry standards, ensuring reliable performance, enhanced efficiency, and operational excellence.

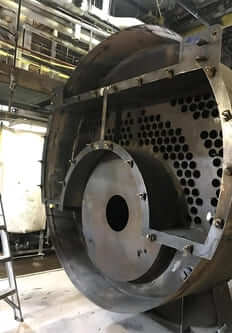

Steam Boiler Manufacturing

Al-Otaibi specializes in manufacturing high-quality steam boiler parts and components, catering to the mechanical engineering needs of modern machine-building companies and industrial enterprises. Our precision-engineered products ensure durability, efficiency, and compliance with industry standards.

Steel Structure Production

We provide a comprehensive range of high-quality steel fittings and components tailored for diverse industrial and engineering applications. Our expert team is dedicated to sourcing and delivering the perfect steel products that meet your specific requirements, ensuring durability, precision, and optimal performance.

Testimonials

Our Team

CNC Operators

Plasma and Laser Cutting

Skilled CNC Operators specialize in programming and operating plasma and laser cutting machines to deliver precise, high-quality cuts. They handle machine setup, calibration, quality control, and adhere strictly to safety protocols, ensuring efficient manufacturing processes and product excellence.

Engineers

Mechanical QC

Mechanical Quality Control Engineers specialize in inspecting piping systems, welding joints, and structural fabrication to ensure adherence to engineering specifications and quality standards. They perform non-destructive testing (NDT), maintain detailed documentation, and ensure full compliance with project requirements and international safety regulations.

Fabricators & Pipe Fitters

Heavy Fabrication & Tasks

Fabricators and Pipe Fitters are skilled professionals responsible for assembling and installing industrial piping systems. They read technical blueprints, cut and align metal pipes, perform precision welding, and ensure compliance with mechanical, structural, and safety standards. Their work supports large-scale construction, oil & gas, and manufacturing operations.

Certified Welders

Welding in Piping Projects

Certified Welders are highly trained professionals who specialize in welding for piping and structural projects. They adhere to international welding standards such as ASME and AWS, perform visual and non-destructive testing (NDT), inspect weld joints, and ensure high-quality, safe, and reliable connections across industrial systems.

Latest Company News

Get in Touch

You can contact us any way that is convenient for you. We are available 24/7 via fax or email. You can also use a quick contact form below or visit us personally. We would be happy to answer your questions.

Head Office at KSA

Work Shop at Riyadh

Work Shop at Saudi Arabia

-

Work Shop 15531, Marat, Industrial city, Riyadh, Saudi Arabia.

-

Head Office 11512, Sahab, King Abdullah II Industrial City, AM, Jordan

-

Work Shop 11512, Sahab, King Abdullah II Industrial City, AM, Jordan