AL-OTAIBI COMPANY

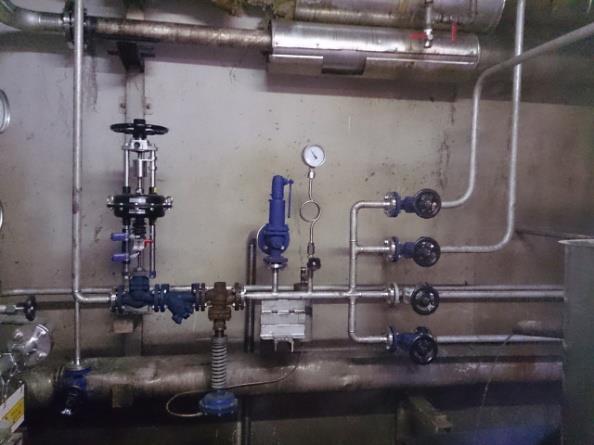

Al-Otaibi Company is a trusted provider of comprehensive construction,

fabrication, installation, and maintenance services tailored to meet the

unique needs of industrial clients.

With a steadfast commitment to quality and excellence, we take pride in

our ability to deliver projects on time, within budget, and to the highest

standards of safety and efficiency.